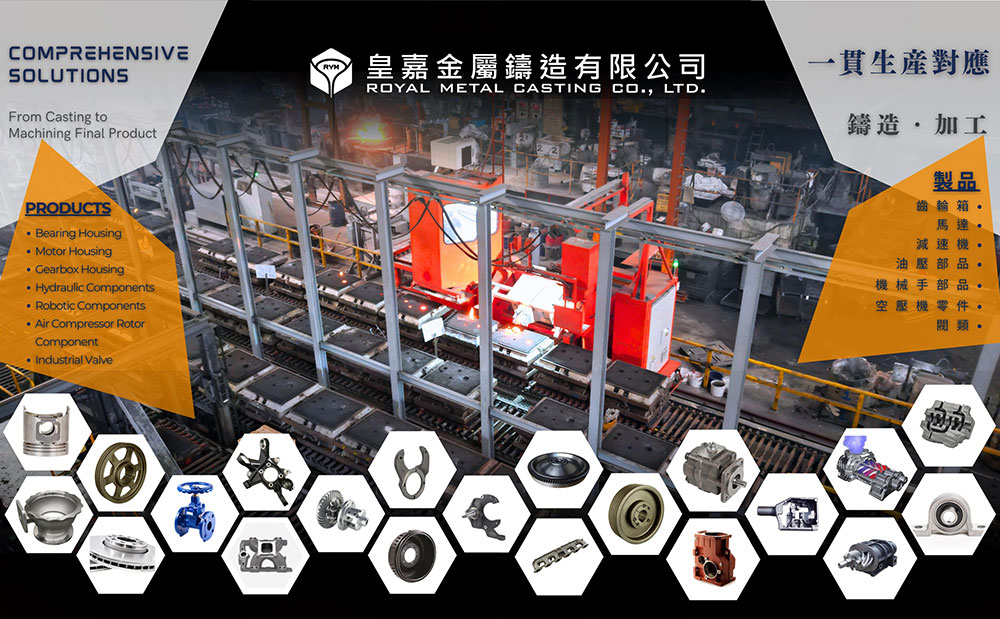

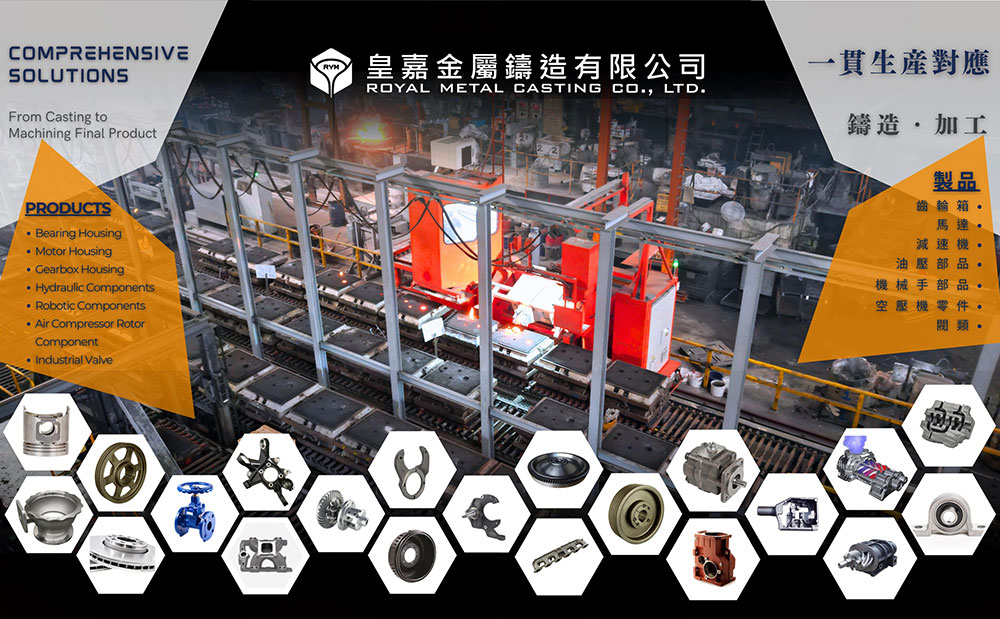

In a rapidly evolving manufacturing landscape, industries are constantly on the lookout for equipment that can elevate efficiency, quality, and reliability. One standout innovation that has gained international traction is the

Automatic Molding Machine, a transformative solution designed to streamline metal casting operations. Royal Metal Casting Co., Ltd. offers advanced molding systems engineered for durability and peak precision, supporting clients in achieving scalable results across automotive, agriculture, and general machinery sectors. Their expertise in gray and ductile iron casting, coupled with robotic automation and mold flow optimization, ensures every molded part meets stringent quality expectations with minimal development delays.

The global push for smarter production practices has led to increased investments in intelligent manufacturing technologies. Businesses are seeking integrated systems that can adapt to dynamic market needs without compromising quality. These advancements are not limited to hardware alone; digital tools for simulation and analytics now play a critical role in shaping production workflows. Leveraging these systems, operators can fine-tune parameters, predict material behaviors, and avoid defects long before the first physical mold is made. In doing so, companies gain a strategic edge in reducing waste and accelerating time to market. As environmental and regulatory pressures increase, solutions that combine sustainability with output consistency have become invaluable assets for manufacturers around the world.

Automatic Molding Machine

Model - Automatic Molding Machine

Production Line Introduction: FBOX and HSP Fully Automatic Molding Machines

To continuously enhance production capacity and quality stability, our company has actively introduced advanced automation equipment, specifically the Shinto FBOX and German-made HSP fully automatic horizontal molding machines. We have built a modern, high-efficiency casting production line.

The entire process, from molding, pouring to mold stripping, is fully automated, effectively reducing human error and greatly improving product consistency and yield.

FBOX Automatic Molding Machine

The FBOX is a high-speed automatic molding system made in Japan, offering the following advantages:

• High-Speed Operation: Capable of producing hundreds of molds per hour, significantly shortening production cycles.

• High-Precision Mold Formation: Utilizes dual control through pneumatic and mechanical pressing to ensure dense and dimensionally stable molds.

• Modular Design: Facilitates quick mold changes and easy maintenance, allowing for flexible and diverse production demands.

• Molding Capacity: 450mm × 550mm × 400mm.

HSP Fully Automatic Molding Machine

The HSP is a high-speed automatic molding system made in Germany, featuring:

• Fully Integrated Automated Process: From sand delivery, molding, mold handling to cleaning, the entire operation is automated, effectively reducing labor dependence.

• Intelligent Monitoring System: Real-time monitoring of production parameters with immediate alerts for any anomalies, ensuring every step meets quality standards.

• Energy-Saving Design: Optimized energy efficiency to lower operating costs and meet environmental requirements.

• Molding Capacity: 800mm × 1000mm × 600mm.

High Automation and Guaranteed Production Quality

By combining the strengths of both FBOX and HSP, we have established a fully automated casting production line characterized by high speed, high efficiency, and high stability.

The core features include:

• Stable Production Quality: High mold consistency reduces defect rates and enhances casting quality.

• Improved Production Efficiency: Automated processes minimize production bottlenecks and boost overall capacity.

• Reduced Human Risk: Automation lowers the need for manual intervention, minimizing operational risks and errors.

• Flexible Production: Rapid product model changes to meet diverse order requirements.

• Wide Product Coverage: From small castings as light as 0.5 kg to large pieces up to 150 kg, our automated production can accommodate a wide range of products.

Royal Metal Casting Co., Ltd.

Automatic Molding Machine

none

999999999

http://schema.org/InStock

USD

2020-12-31

https://www.ironcastingsupplier.com/en/automatic-molding-machine-1.html

Royal Metal Casting Co., Ltd.

90out of

100based on

100user ratings

With over four decades of machining excellence, Royal Metal Casting Co., Ltd. continues to redefine the benchmark for foundry performance. This Automatic Molding Machine is designed to integrate with high-capacity lines, offering manufacturers the ability to reduce labor dependency while maintaining dimensional accuracy. As trusted suppliers and seasoned exporter from Taiwan, the company consistently delivers results that outperform manual processes in speed and consistency. Royal Metal Casting Co., Ltd.'s unique combination of automated finishing and custom machining ensures that each product represents the Best in class, making them the ideal partner for clients seeking long-term value and technological superiority.

As demand rises for tailored solutions that meet diverse industrial specifications, the role of innovation becomes even more crucial. Forward-thinking production teams are turning to modular design systems that allow for easier upgrades and maintenance without full-scale overhauls. This approach not only extends equipment lifespan but also boosts operational uptime. Moreover, user-centric interfaces and AI-assisted diagnostics are reducing learning curves for operators, facilitating smoother transitions during process scaling. These shifts are paving the way for a new era where adaptability and precision are key competitive drivers. In this context, advanced molding solutions are not just machines—they are enablers of next-generation manufacturing excellence.

Enquiry

Now

Products List